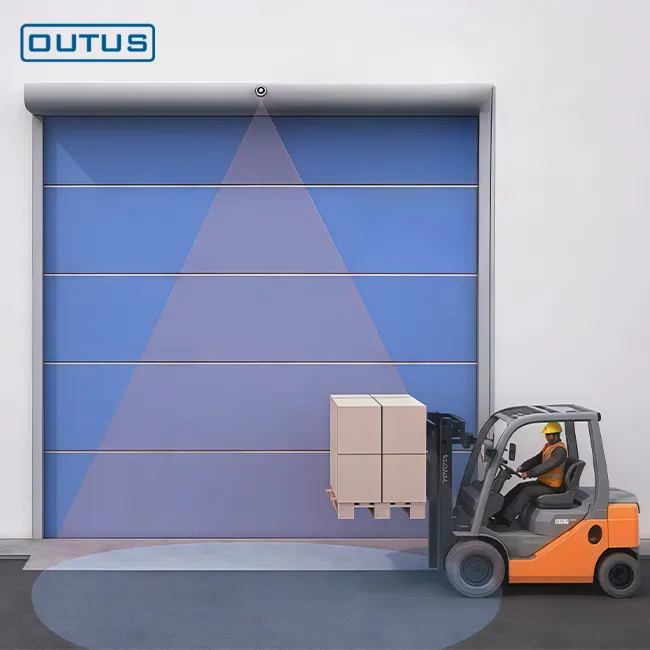

For the purpose of smooth work operations, as well as safety and climate control, industrial automatic doors become essential in warehouses, manufacturing plants, and logistics centers. Like any other electro-mechanical system, they might have problems from time to time that makes operations to discontinue. With some knowledge about the most common problems and solutions for them, the problems can be mitigated. OUTUS are expert in manufacturing sturdy Industrial Doors, shares some troubleshooting guides.

Improper Opening and Closing of the Door

This is common and different causes can interfere with this process.

Cause: An obstruction in the door path, misalignment of the track, or a defective limit switch results in the door being completely open or shut.

First of all, check the track and the door path for any debris or hindrance. Check if there is any visible misalignment of the track. For OUTUS Industrial Doors, check the manual for recalibration of the limit switch. This procedure ensures that the door goes to the correct open and close positions.

Unresponsive or Faulty Sensors

The safety sensors and activation sensors are the "eyes" of the door. In their absence, the door might remain dangerously open or close.

Causes: Dirty lenses, misalignment, or other physical damage to the sensors could cause the disorder. Thirdly, electrical connection failures are very common.

Solution: Clean the sensor lenses carefully and check for alignment between the paired sensors. Check the wiring for damage or loose connections while ensuing. Most of the OUTUS doors have indicator lights on their sensors for quick diagnosis of such issues.

Motor Overheating and Power Supply Problems

When the motor overheats or there is inconsistency in the power supply, abnormal operation starts followed sometimes by shutting down.

Overheating may be caused by excessive use, voltage fluctuation, or mechanical obstruction forcing an exceed motor workload. Power Supply disruption may be due to tripping circuit breaker or faulty wiring.

Solution: In case the motor has an internally mounted thermal protector, let it cool down. For the power supply, check the mains and circuit breaker. Also, ensure the door travels freely through hand movement (when disconnected from power) to rule out mechanical binding. OUTUS Automatic Door Operators are equipped with thermal protection; however, in case of persisting overheating, it should be referred to a professional.

Slow or Noisy Door Operation

If a door is working slower than normal or grinding or squeaking sounds are suddenly coming out, it needs urgent attention.

Causes: Noise and slow speed are generally related. Majorly these include lack of lubrication on tracks, rollers, and hinges, but other causes could include worn or damaged rollers or components, a faulty drive mechanism.

Solution: Lubrication of all moving parts should be done in accordance with the OUTUS maintenance guideline. The rollers and hinges should be checked for wear and tear against their specifications and be replaced if necessary. Adhering to this simplest of maintenance can greatly enhance performance and extend office life.

Control System Errors and Malfunctions

Without any doubt, the control board is the brain of an automatic door. It is this brain that causes unpredictable behavior due to either software glitches or hardware failure.

Control systems can fail for many reasons: power surges, moisture damage, component aging, simply a corrupted program or faulty connection.

Solution: A very basic first step is to reset the plant by cutting power for a few minutes and restoring it. If the problem persists, observe the control panel display for error codes (see OUTUS manual for code definition). Almost always, the diagnosis and repair of such control board problems should be left to professionals-for the safety of the user and appropriate operation of the unit.

With the above troubleshooting tips, most day-to-day challenges can be resolved. However, as always, prevention is better. Outfitting your OUTUS Industrial Doors with regular professional maintenance means that small problems will be identified and dealt with before they become costly downtime. Partnering with a reputable manufacturer like OUTUS ensures you will be able to source genuine parts and request expert technical assistance that will keep your operations smooth and safe.